Reverse engineering - road to CAD

Reverse engineering is a process that allows you to transform an existing physical object into a computer model, known as a CAD (Computer-Aided Design) model. It is an extremely useful tool in the field of engineering, allowing you to accurately reconstruct the geometry and function of objects in a virtual environment. In the following article, we will present the steps of reverse engineering, define the concept of reverse engineering itself, and discuss its advantages and applications.

Reverse Engineering - What Is It?

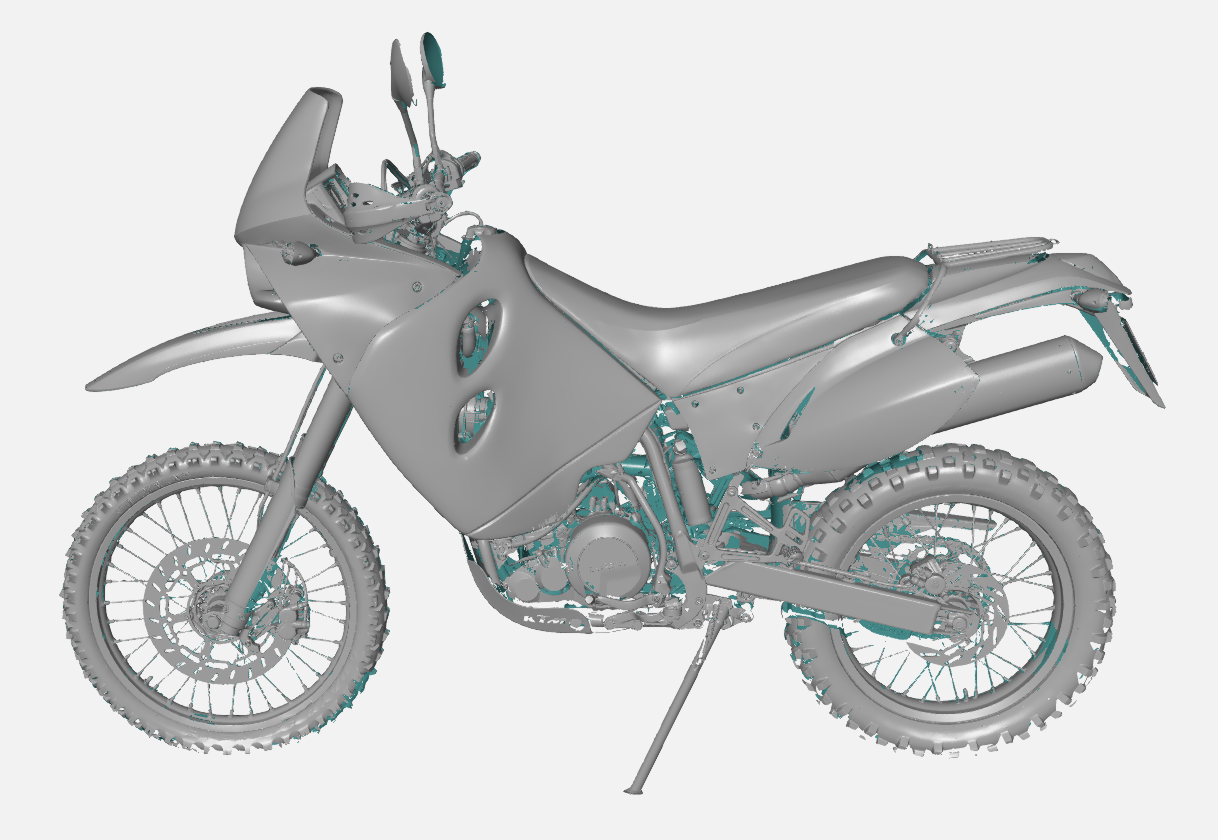

Reverse engineering is a process aimed at recreating a real object in digital form. This is especially important when there is no technical documentation available for a given object, and there is a need to replicate it, introduce modifications, or understand its operation. In practice, this means that when a CAD model or technical documentation is needed for a specific part, component, or entire structure, a 3D scan of the complete geometry is first performed, and then, based on the obtained data, a parametric model is created which can be used for design, optimization, or replacement.

Reverse Engineering - Step by Step

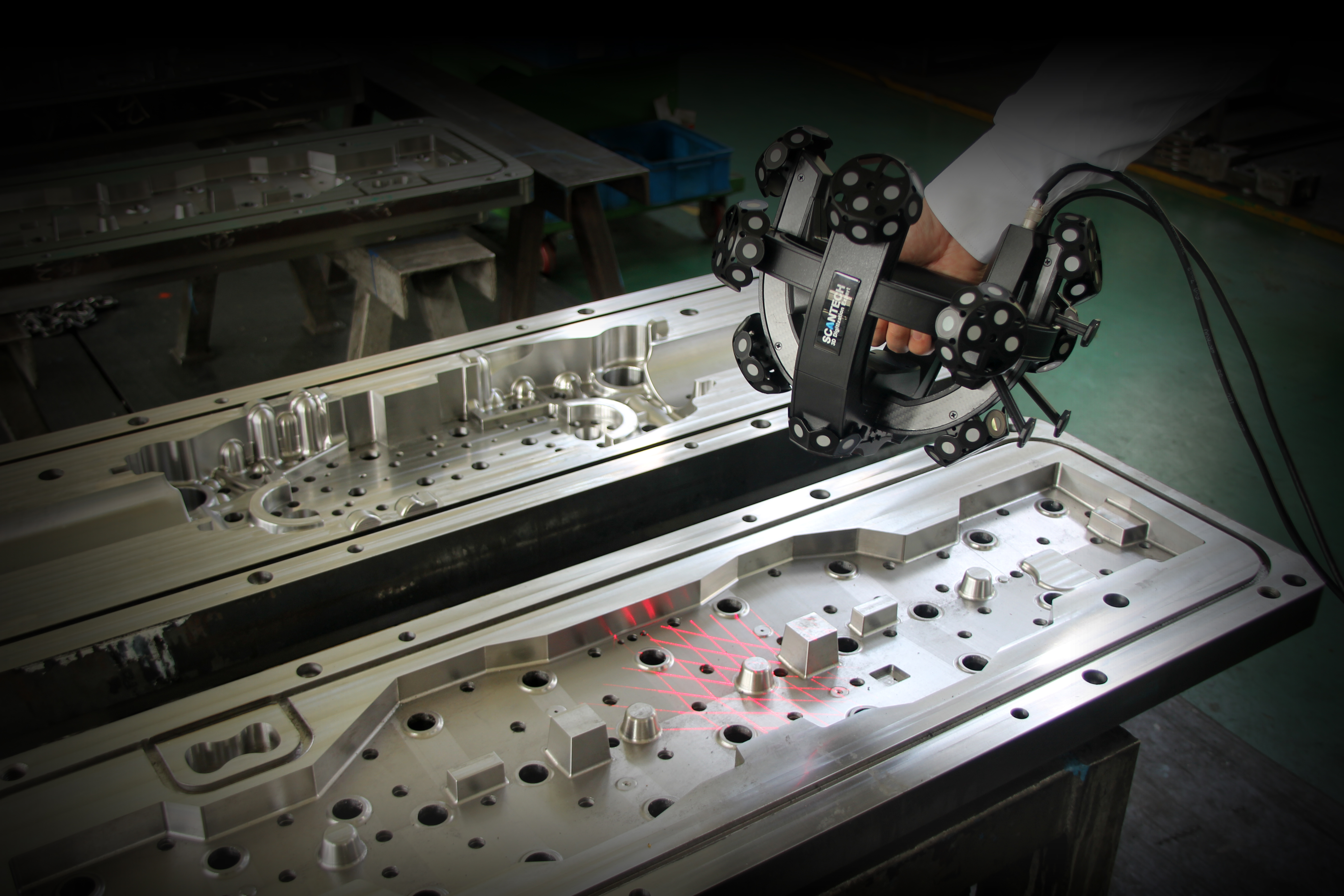

Step 1. Scanning the object: The process begins with scanning the real object. Advanced 3D scanners are used to collect precise data about the shape and structure.

Step 2. Creating a point cloud: The scan data is processed into a point cloud that contains information about the three-dimensional location of points on the object's surface.

Step 3. Processing the point cloud: Specialized software processes the point cloud, removes unnecessary artifacts, and creates a dense, accurate surface representation. The resulting model is a mesh composed of thousands of small triangles.

Step 4. Creating CAD surfaces: CAD surfaces are created from the mesh model to represent the shape of the object. This is the stage where the model begins to take its final form.

Step 5. Optimization and Modifications: Engineers can adjust the model, remove inaccurate details, smooth surfaces, or make changes according to project requirements.

Step 6. Generating Technical Documentation: Finally, engineers generate technical documentation of the CAD model, which can be used for production, analysis, or further modifications.

Advantages of Reverse Engineering

- → Restoration without documentation: Allows you to recreate an object without access to its original technical documentation.

- → Modifications and Improvements: Makes it possible to modify and improve existing objects.

- → Accuracy and Precision: Provides the ability to create highly accurate models, which is crucial in advanced fields such as aerospace or medicine.

Reverse engineering is becoming a key practice that supports the design, optimization, and repair of real parts in many industries. The ability to digitally reproduce entire, even very complex geometries using precise 3D scanners has driven the dynamic development of reverse engineering, supporting redesign and the creation of new, optimized CAD models based on existing parts.

Industries Using Reverse Engineering

- ✔ Automotive: Car parts, body panels, rims, car interior components.

- ✔ Marine industry: Boat hulls, yacht cabins, motorboats, and jet skis.

- ✔ Heavy industry: Castings, molds, dies, forgings, stamping dies.

- ✔ Medicine: Implants, prostheses, and orthoses.

- ✔ Energy: Turbines, hubs, shafts, rotors, and blades.

- ✔ Architecture and Archaeology: Copying and restoring monuments, antiques, sculptures, works of art, and archaeological sites.

Reverse Engineering Software

Geomagic Design X: A dedicated reverse engineering platform supporting all major 3D scanners, importing raw data, and compatible with all file formats. It is a professional tool for creating precise solid models, editing triangle meshes created from point clouds — for example, mesh optimization, hole closing, and more.

Fusion 360: In the reverse engineering process, this software is often used to edit a CAD model to adapt it to the client’s requirements, for example, to introduce modifications to the original.

Summary

Reverse engineering in creating CAD models is the foundation of a modern approach to design and production. Through precise process steps, engineers can recreate real objects in a virtual environment, which is invaluable across various industries, from industrial manufacturing to medicine. However, it should be remembered that this process — from 3D scanning to data processing and detailed modeling — requires advanced tools and skills.

The development of dedicated reverse engineering software, such as Geomagic Design X and Fusion 360, allows for even more efficient and precise creation of CAD models. This makes the process more accessible and effective for a wide range of engineering tasks.

In the future, we can expect further advances in the automation of reverse engineering processes, which will shorten the time required to create CAD models while increasing their accuracy. Reverse engineering remains a key tool for innovative projects and will continue to evolve, supporting technological development on many levels.