Mission

Welcome to 3D Customs. We are a team of specialists with a passion for modern technologies, who have been passionately involved in 3D scanning, quality control, reverse engineering and 3D printing for years.

Our experience and advanced tools allow us to implement the most demanding projects, from the concept stage to the final product. We believe that the future of industry and design lies in 3D technology.

Our mission is to provide comprehensive solutions that support innovation and development in various industries. Thanks to our services, customers can not only improve their production processes, but also implement new, groundbreaking solutions.

Services

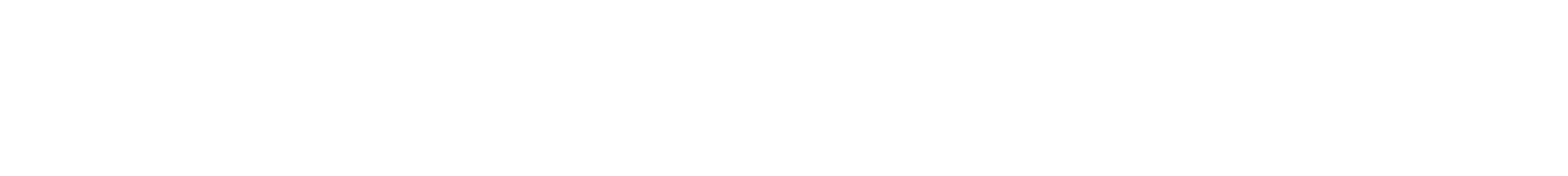

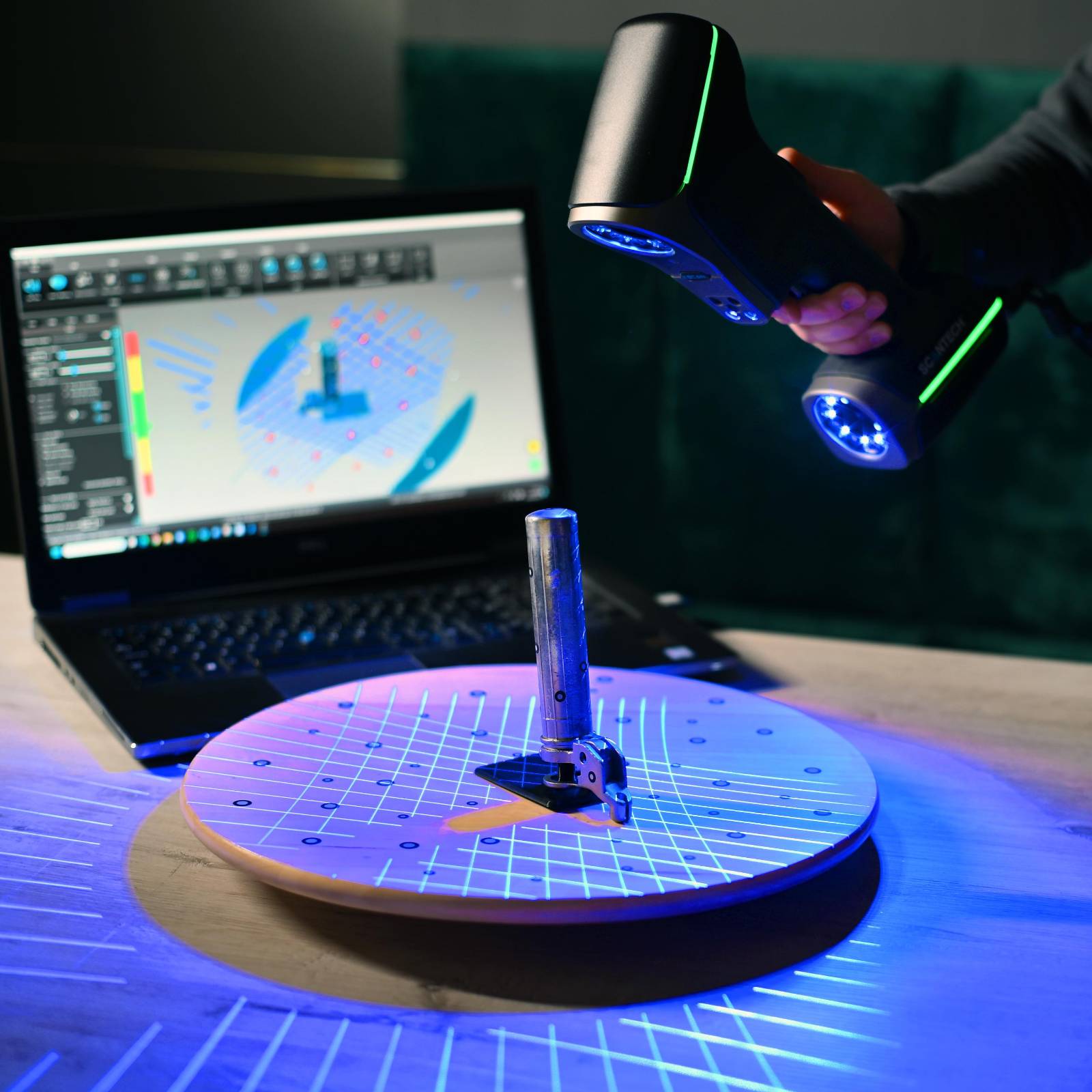

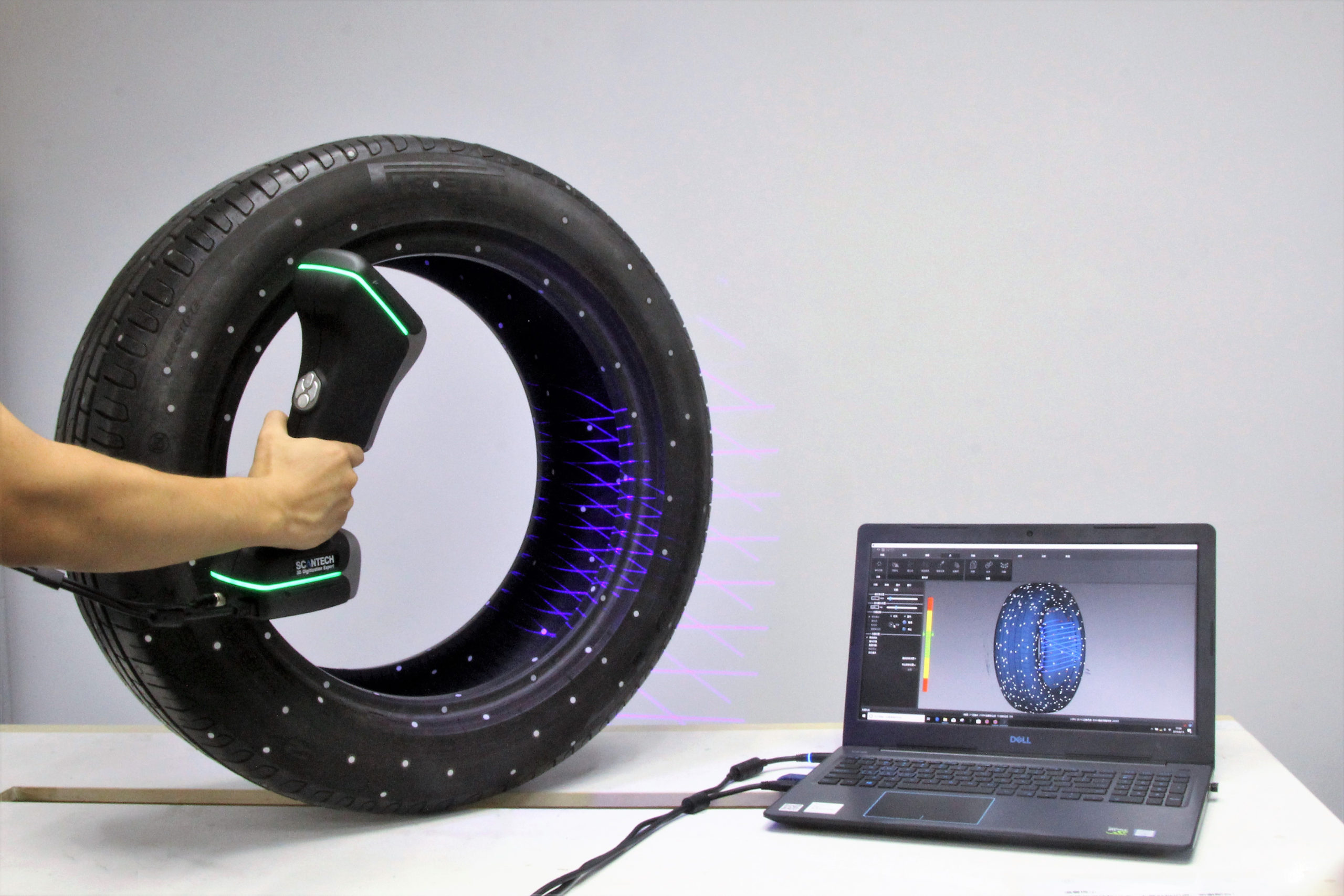

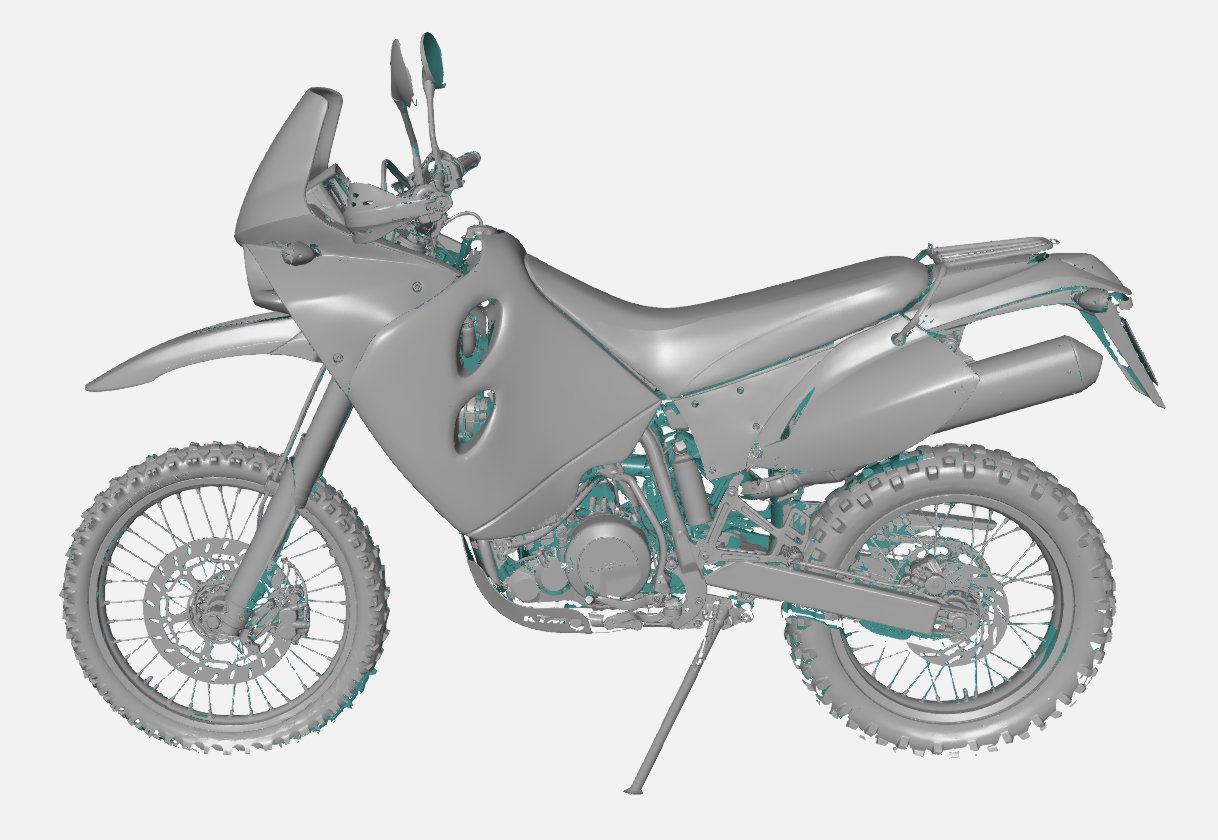

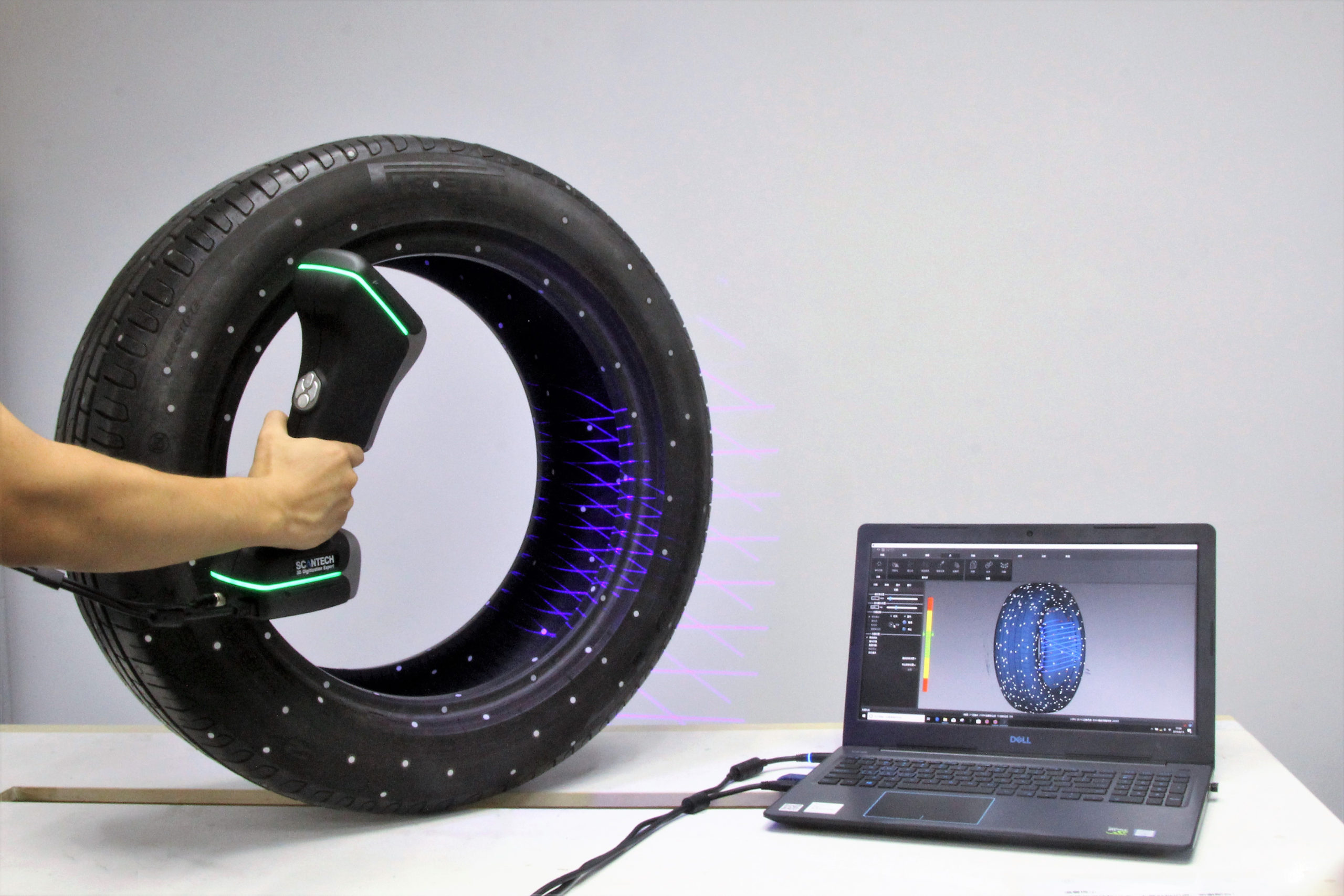

Professional 3D scanning services for industry and engineering

We specialize in precise 3D scanning, which is widely used in industry, engineering, architecture and many other sectors. Thanks to advanced technologies and modern 3D scanners, we offer accurate representation of objects in the form of digital models, ideal for purposes such as reverse engineering, quality control, prototyping or creating technical documentation.

The scope of our 3D scanning services:

- 3D scanning for reverse engineering

We create CAD models based on physical objects, allowing them to be analyzed, reconstructed or modified. This is an excellent solution for modernizing parts or recreating elements that do not have technical documentation. - 3D scanning of products

Precise representation of product geometry enables their verification, archiving and optimization in design and control processes. - 3D scanning of prototypes

Digitization of prototypes and concept models allows for detailed analysis, testing and optimization of designs before they are introduced into series production. - With the help of 3D laser scanners, we implement precise reproduction of large structures and components, meeting the requirements of even the most advanced projects.

Why choose 3D scanning service from us?

- High precision of measurements

Our 3D scanners achieve an accuracy of up to 0.02 mm, which guarantees the highest quality of reproduction of even the most complex details. - We

use advanced laser scanners and specialized software to provide accurate and detailed 3D models in a short time. - Fast and flexible implementation

We adapt to the needs of our customers, offering timely 3D scanning services throughout the country. - We

have mobile scanning systems, thanks to which we carry out projects both at our headquarters and directly at the customer's site. - We

provide comprehensive support at every stage of the project – from technical consultations, through analysis of results, to the final delivery of documentation.

Application of 3D scanning technology

- Reverse engineering – creating CAD documentation based on scans of physical objects,

- Quality control – precise dimensional analysis and verification of product compliance with design requirements,

- Prototyping – digitization and analysis of prototypes before serial production,

- Technical documentation – detailed mapping of objects for archiving or modernization purposes,

- Industry and production – optimization of design and control processes based on accurate 3D models,

How to order a scan 3D?

If you need professional scanning services 3D, please contact us. We offer free consultation and individual project valuation. Our team of specialists will help you choose the best solution tailored to your needs.

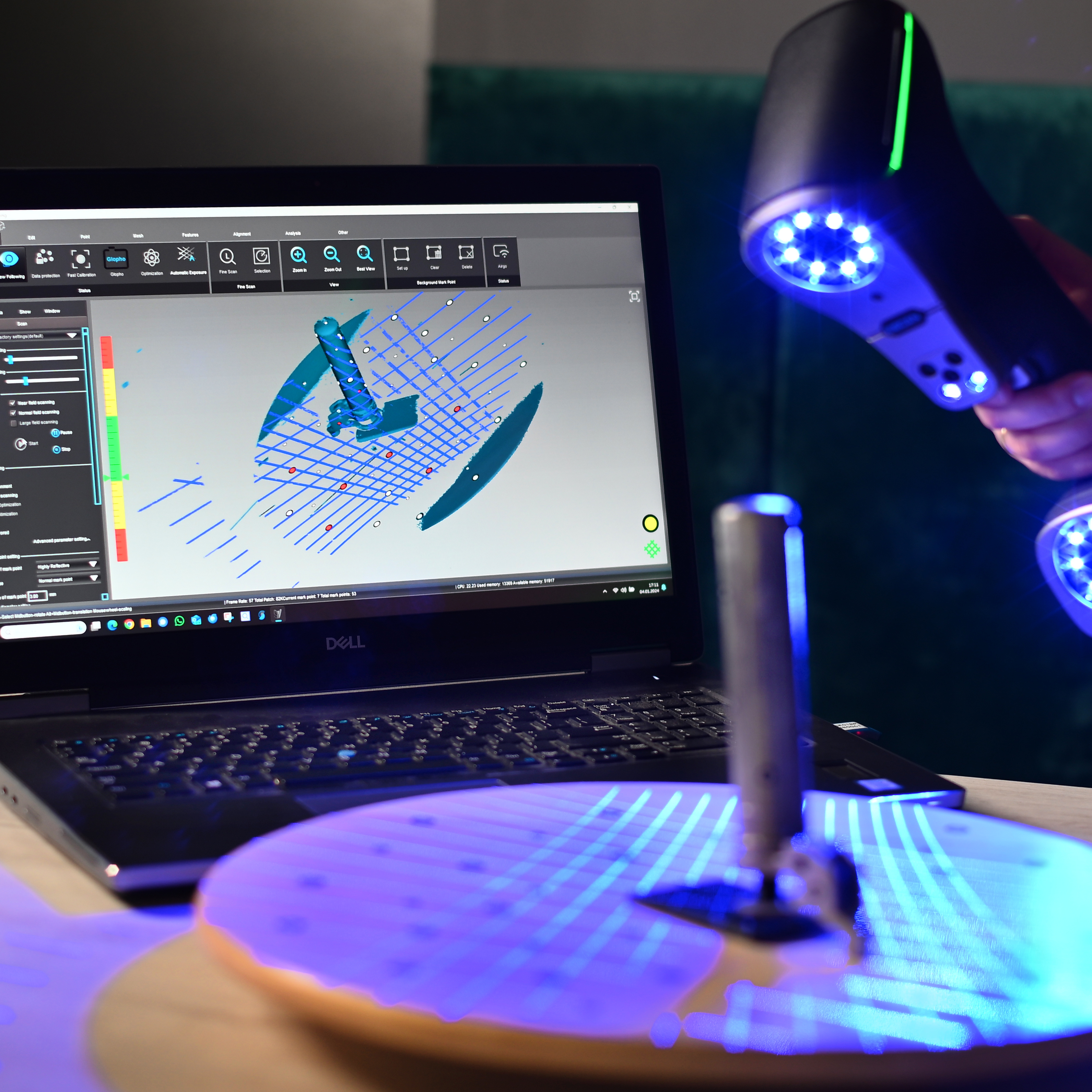

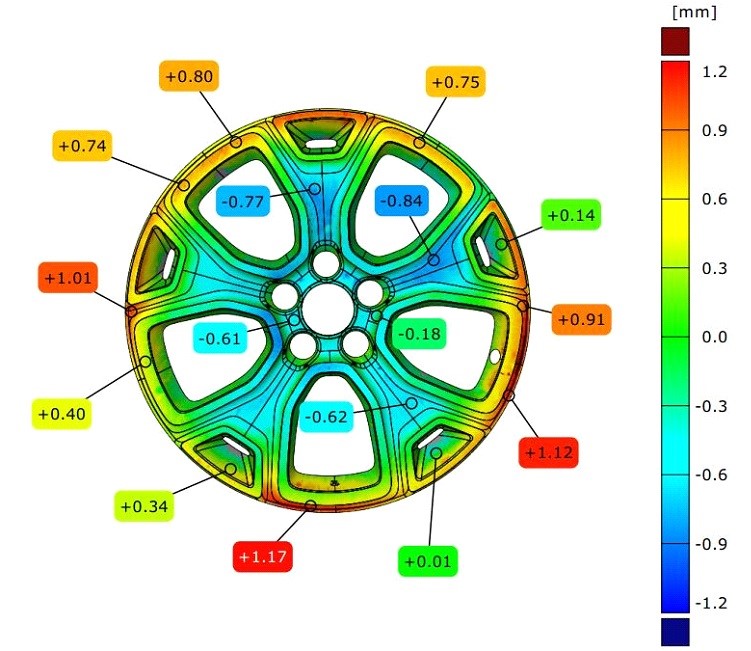

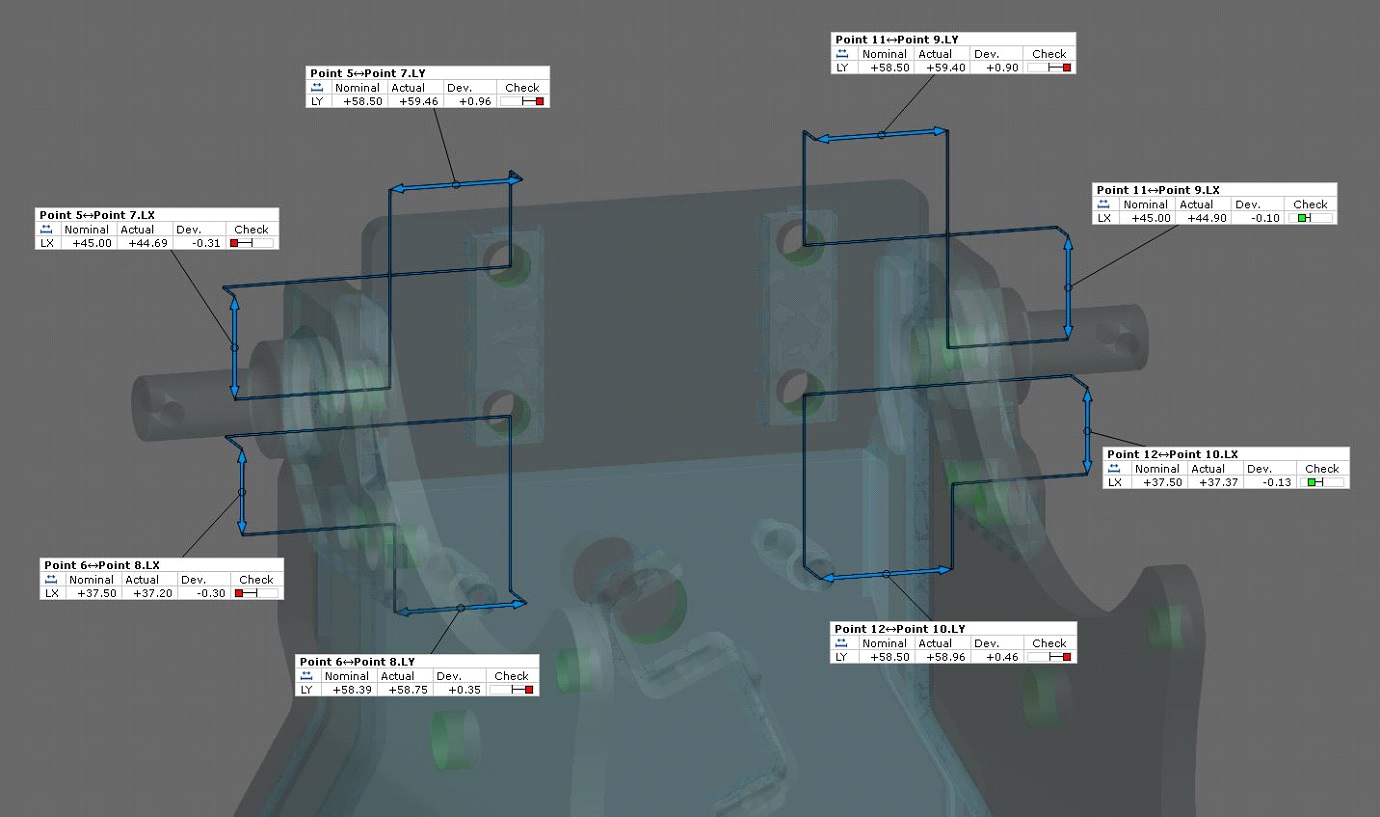

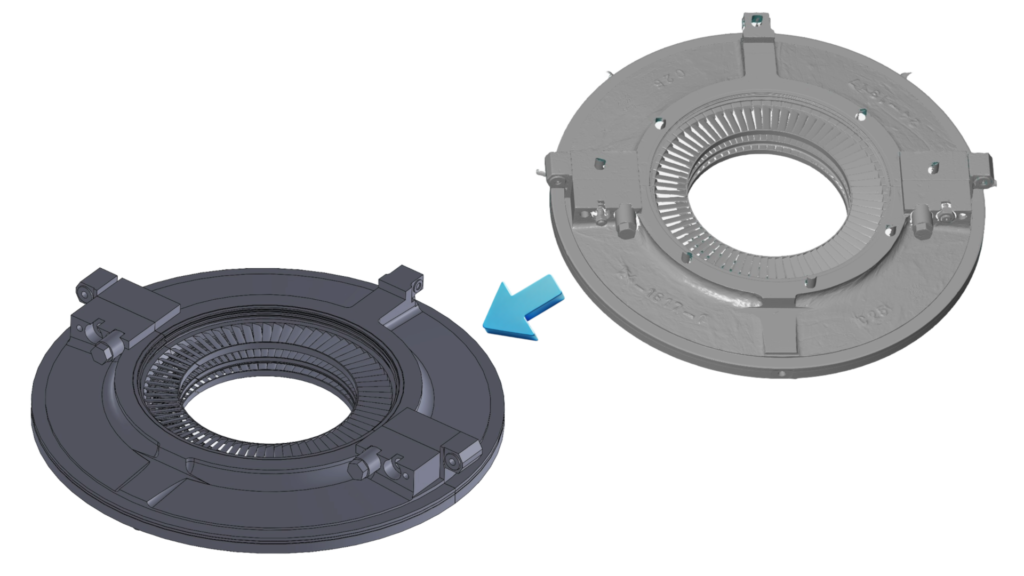

Professional quality control using 3D scanning

We offer comprehensive 3D quality control servicesthat help companies in various industries maintain the highest standards ofproduction. Thanks to modern 3D scanning technologies, we precisely verify thecompliance of products with design requirements, minimizing the risk oferrors and optimizing production processes. Our solutions are ideal for both massproduction and precision technical components.

Our offer of quality control with the use of 3D scanning:

- Product Quality Control

Precise inspection at every stage of production. Our 3D measurements ensure that products are fully compliant with standards and technical specifications, which is crucial to maintaining quality. - 3D dimensional inspection

We use advanced 3D scanners to accurately measure the geometry of the elements. This allows for dimensional analysis of even the most complex components. - Visual inspection

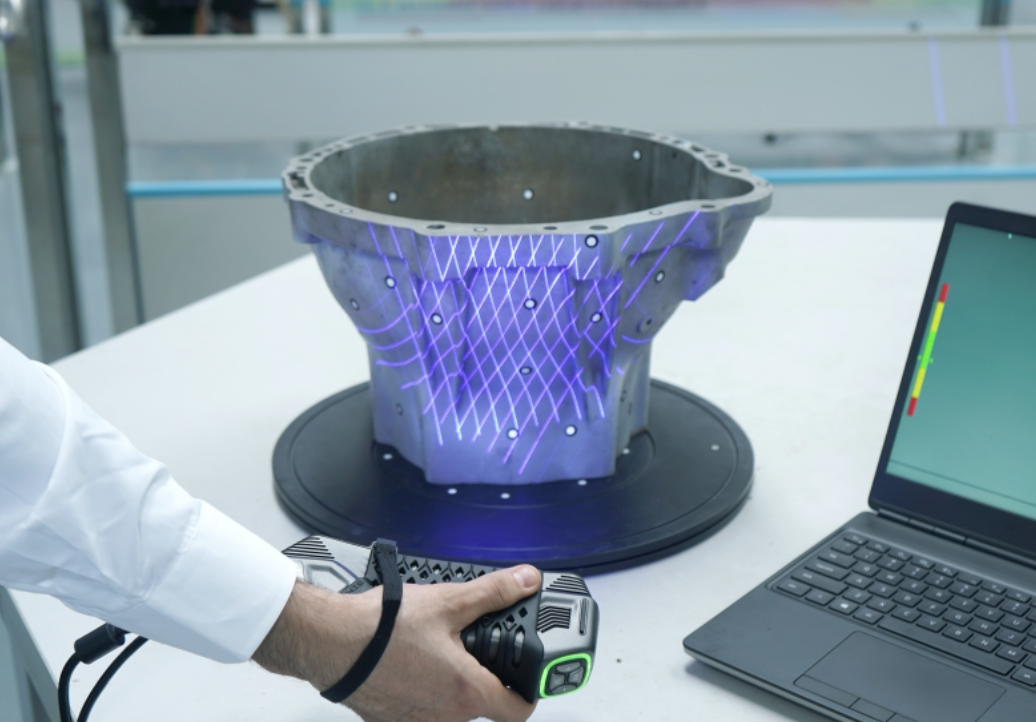

The digital representation of the surface of objects allows you to quickly identify defects, deviations and damage. - Comparison with the CAD model

We analyze the 3D scans for compliance with the original CAD model. We detect even the smallest deviations from the design, eliminating the risk of dimensional inconsistencies. - We

provide detailed measurement reports containing analytical data, inspection results and a graphical presentation of quality control results in the form of a color map of deviations.

Why Choose Our 3D Quality Control Services?

- Elimination of production errors

Our 3D quality control services allow you to quicklyidentify defects, deformations and dimensional deviations at the productionstage. This minimizes the risk of complaints, material loss, and rework costs.

- Fast and timely order processing

We understand the dynamic production environment. We offer timely and flexible service delivery so that your processes do not have delays.

- Comprehensive measurement reports

We offer detailed quality control reports, includingmeasurement data, 3D visualizations and deviation analysis. Our reports complywith the requirements of industry standards and can be used as qualitydocumentation in certification processes.

- We tailor our services to the needs of your company, regardless of the scale or complexity of the project.

Application of 3D Quality Control:

- Continuous

quality control on production lines allows you to maintain repeatability and compliance with quality standards. - Precision Manufacturing

Thorough verification of technical components, especially in industries such as aerospace, automotive, and precision industry. - Prototyping

Analysis of the compliance of prototypes with the CAD design allows you to detect errors and optimize the design before serial production. - Elimination of production errors

3D quality control allows for quick identification ofdefects, deformations and dimensional deviations at the production stage.

How to use our quality control services?

Contact us today for a free consultation and a customizedquote. Our team of experts will help you choose the best solution foryour needs. With our 3D quality control services, you can be sure that yourproducts meet the highest standards of precision and quality.

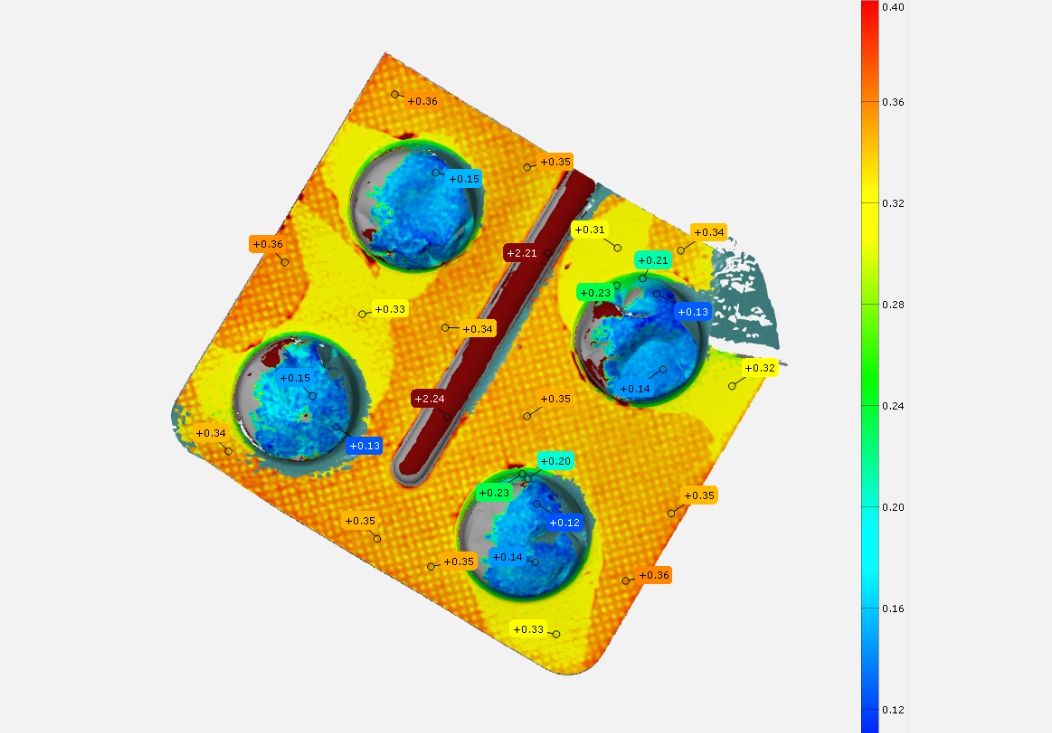

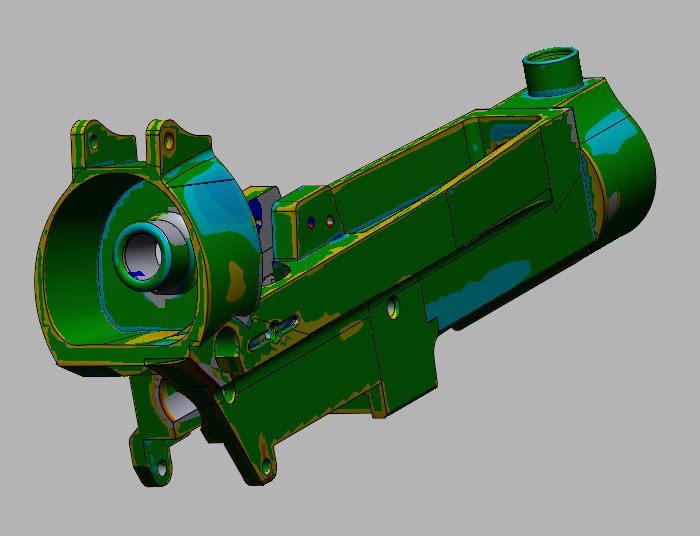

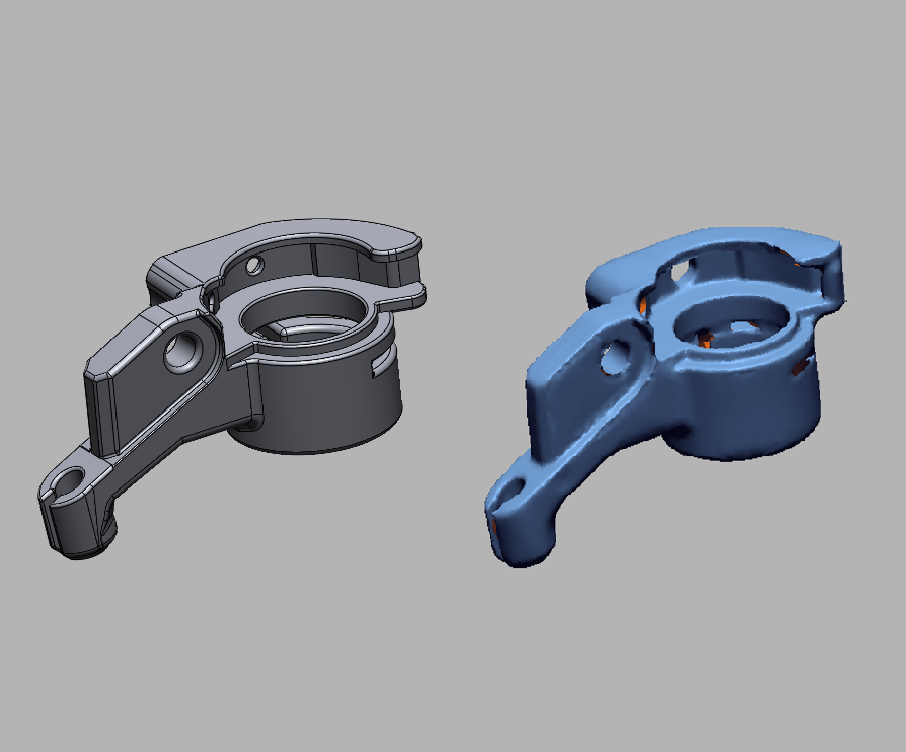

Professional Reverse Engineering – Reconstruction,modernization and optimization of products

We offer comprehensive reverse engineering servicesthat allow for precise reproduction and optimization of components, parts andproducts for companies from various industries, machinery industry,aviation, automotive, energy, architecture or medicine, where precisemodels and reconstruction of objects are crucial. Reverse engineering is areliable tool to support production, modernization, and analytical processes incompanies. With our advanced technologies and experience, we help you reducecosts, streamline production, and create accurate CAD models and spare parts.Using our services will allow you to optimize your processes, improveefficiency and maintain competitiveness in the market.

Our offer of reverse engineering services:

- Creation of CAD models

Precise reproduction of existing objects in the form of digital 3D models. The obtained CAD models can be used in design and production processes, as well as in technical analyses. - We recover missing technical documentation or create it from scratch for objects that do not have original drawings and CAD data.

- Product Modernization and Optimization

We analyze existing products for improvements in functionality, robustness and performance. Optimization allows you to adapt elements to modern standards and technical requirements. - We reproduce the geometry of hard-to-find or no longer produced spare parts. This allows your company to continue production or repairs without long downtimes.

- Competitive Analysis

We use 3D scanning to map and analyze competitors' products, allowing us to understand their design and find opportunities for improvement.

Why use our reverse engineering services?

- Support for prototyping and production

With digital 3D models, it is possible to create prototypes faster, analyze them for errors, and optimizedesigns before they are put into series production.

- Fast and timely order fulfillment

Our experienced team of engineers minimizes the time needed to complete services, supporting the continuity of your production and repair processes. - Cost optimization

Thanks to the reconstruction of spare parts and reconstruction of technical documentation, we eliminate the need for costly purchase of original components or their long-term search. - Individual approach to each project

Each project is treated individually, adapting our services to the specific needs of the client. We offer full technical support and advice at every stage of implementation, adapting the reverse engineering process to the specific needs of your company.

Application of Reverse Engineering:

- Ideal

for companies that need precise CAD models of worn, old or damaged components. - Modernization and product improvements

We enable the modification of existing structures in order to improve their technical parameters, functionality and performance. - Spare parts production

Recreate the geometries of parts that are difficult to obtain, no longer produced or require individual adjustments. - Reconstruction of technical documentation

Creating complete technical drawings for objects without existing documentation. - Restoring the functionality of old elements

Reverse engineering allows worn or damaged components to be refurbishedand replaced, restoring them to full functionality and extending the lifecycle of the product.

- Competitive analysis

Accurately replicate your competitors' products to identify their strengths and weaknesses and develop better technology solutions.

How to order our reverse engineering services?

Contact us today for a free consultation and an individual project quote. Our team ofexperts will support you every step of the way – from 3D scanning to CAD modelcreation to product optimization. Thanks to our services, you will gain timesavings, precision of reproduction and competitive technological solutions.

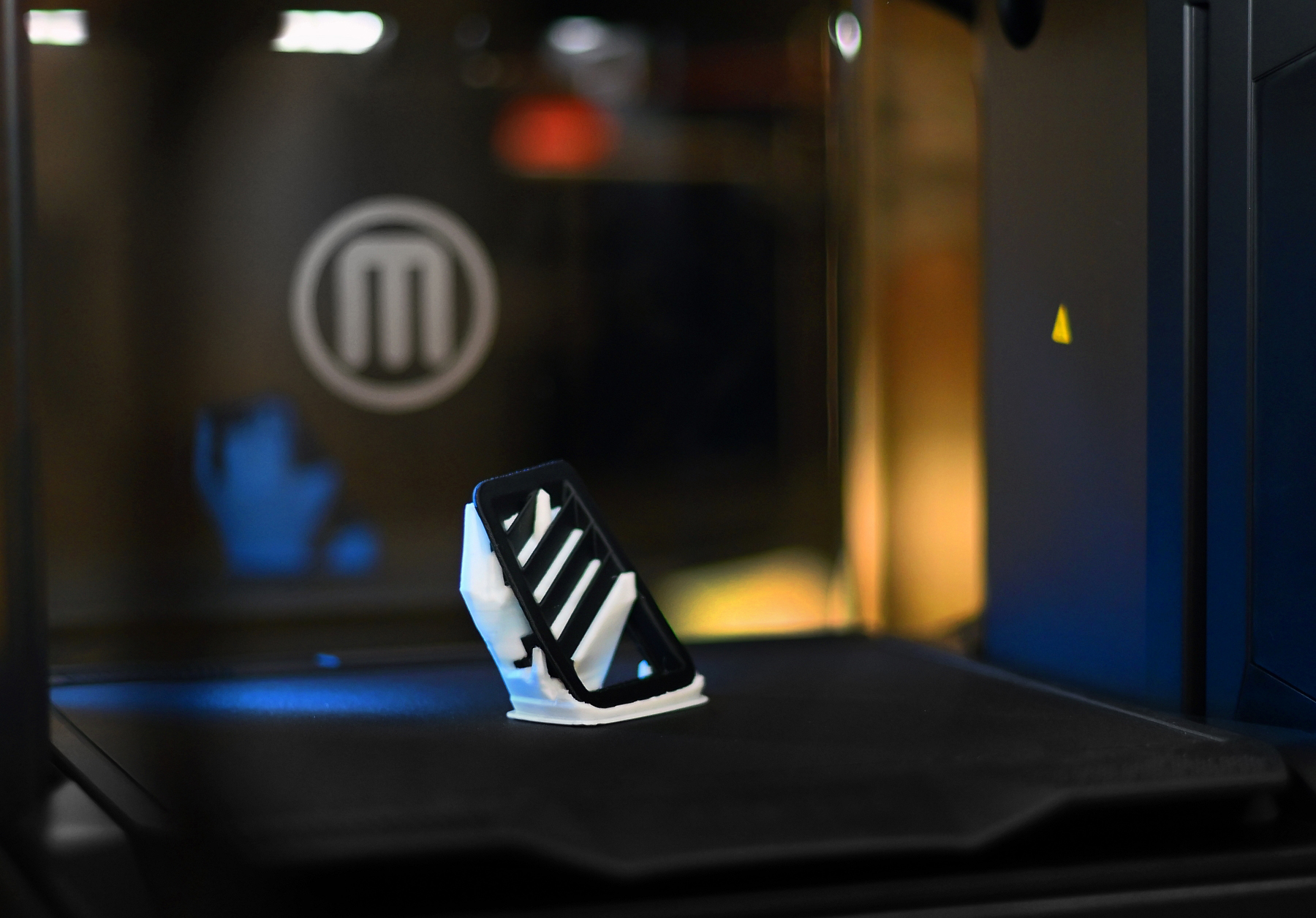

3D Printing Services for Industry – Innovative solutionsfor your company

We offer professional 3D printing services that arethe perfect solution for companies in various industries, such as automotive,aerospace, medical, architecture, and manufacturing. Thanks to modern 3Dprinting technologies, we carry out projects with high precision, including prototypes,production of non-standard partsand finished products tailored to the individual needs of our customers.

Our 3D Printing Services:

- 3D printing of prototypes

We make functional prototypes that allow you to test and optimize designs before starting serial production. With rapid prototype manufacturing, our customers can speed up the process of bringing products to market.

3D printing enables the production of short-run batches, non-standard parts and elements with complex geometries. It's perfect for businesses that need high-quality, high-precision parts, but in smaller quantities.- We

carry out individual orders, including spare parts, tools, architectural and medical models and other products. We offer a wide range of materials, which allows you to create customized solutions. - 3D printing in various materials

We offer 3D printing in a wide range of materials, such as plastics, resins and composite materials, which meet the specific requirements of projects and ensure their high strength and functionality. - Post-processing and finishing

We provide comprehensive finishing services, such as surface treatment, painting, assembly of elements, so that the finished products meet the highest standards of quality and aesthetics.

3D scanning

Why Use Our 3D Printing Services?

- Precision and accuracy

Our modern 3D printers guarantee high precision of detail reproduction , even in the most complex projects. Thanks to this, each element is accurately reproduced, which translates into the quality of the final product. - Fast execution

We offer express execution of orders, which allows us to speed up the process of introducing products to the market. Thanks to 3D printing, the lead time is much shorter compared to traditional production methods. - We

use the latest 3D printing technologies, which enable the production of durable and aesthetic products with complex geometries, meeting the highest quality standards. - 3D

printing is an ideal solution for both individual orders and short-run production. Thanks to this technology, we are able to adapt to the specific needs of different customers. - 3D

printing allows you to reduce production costs by eliminating the need to create expensive molds and tools, which is especially beneficial for short-run production and prototyping.

3D Printing Application:

- Prototyping

Printing functional prototypes allows for rapid product testing and development, which speeds up the design process and helps avoid costly manufacturing errors. - Spare parts production

Rapid production of custom spare parts and components, especially those with complex geometries that are difficult to obtain or expensive to produce. - Architecture and construction Creating

architectural mock-ups, building models and structural elements in various scales, which allows for precise mapping of projects before their implementation. - Automotive & Aerospace

Manufacturing of high-precision parts and tools tailored to the specific requirements of the industry, while maintaining quality and safety standards. - Printing

anatomical models, implants and surgical instruments tailored to the individual needs of patients, which allows for precise adaptation to the specifics of treatment.

How to order 3D printing services?

Contact us now to take advantage of our professional 3Dprinting services. We offer:

- Free consultation,

- Individual pricing, tailored to your needs.

Our team of specialists will help you with any project, fromconcept to finished product, providing professional advice atevery stage of implementation.

Achievements

+258

NUMBER

CUSTOMERS

+672

ORDERS

+614 KG

MATERIAL

Are you interested in collaborating?

Project description

Type of service

Technical specification

Deadline for completion

FAQ

The standard lead time for business clients depends on the scope of the order, the complexity of the project and the required production processes. 3D scanning services are completed within 2 business days from the moment the client accepts the deadline. Projects that require additional stages, such as 3D printing, quality control or reverse engineering, can be completed within a time frame of 1 to 6 weeks, depending on the complexity and individual arrangements. Each order is subject to detailed analysis and a completion schedule that has been agreed with the client.

We offer a wide range of payment methods, tailored to the needs of businesses. We accept bank transfers, fast online payments (including BLIK and electronic transfers) and credit card payments. For regular contractors, it is possible to establish individual payment terms, such as deferred payment or installment settlements. In the case of high-value orders, cooperation based on framework agreements is also possible.

Yes, for business customers placing wholesale orders we offer the possibility of negotiating price terms. For large-scale orders it is possible to establish individual discounts, preferential delivery times and flexible payment terms.Our goal is to adapt the offer to the customer's needs, which allows for cost optimization and ensuring long-term cooperation based on favorable commercial terms.

Yes, we fulfill orders for customers from all over Europe, and in justified cases also from outside its borders. International shipping is carried out through renowned logistics companies, which ensures safety and timely deliveries. The cost and delivery time depend on the recipient's location, the selected method of transport and the specifics of the order. In the case of shipments of non-standard dimensions or requiring special transport conditions, we offer individual consulting in the field of logistics.

Custom-made products, including items manufactured using 3D scanning, reverse engineering or 3D printing, are not subject to standard return policies due to their unique nature and individual adaptation to customer requirements. An exception is when the product has a manufacturing defect resulting from manufacturing errors or non-compliance with the agreed technical specification. Standard products from our offer are subject to return within 14 days of delivery, in accordance with applicable law.

We use advanced 3D blue laser scanning technology. Laser scanning provides the highest precision in detail mapping, allowing the recording of even very complex geometries with micrometer accuracy. The technology used allows for effective mapping of most technical elements.

Yes, our 3D scanning methods are completely non-contact, which means that the digitization process does not affect the physical structure of the scanned objects. This allows you to safely scan elements made of fragile materials such as ceramics, glass, or delicate plastics. In addition, the technologies we use do not emit heat or radiation that can affect the mechanical or chemical properties of the object. In the case of particularly delicate or unstable surfaces, we additionally use stabilization techniques, such as appropriate support or low-adhesive protective preparations.

3D scanning is widely used in many industrial and scientific sectors: - In reverse engineering, it allows the reproduction of the geometry of existing elements in order to reconstruct or modernize them. - In quality control, it allows for a precise comparison of the obtained scans with the reference model, detecting even the smallest deviations from the technical specification. - In industrial design, it supports rapid prototyping and design optimization. In addition, this technology is used in medicine (e.g. for creating custom implants), archaeology (for digitizing monuments) and in the automotive and aviation industries.

Despite the advancement of 3D scanning technology, there are some limitations. One of the challenges is scanning transparent objects that strongly reflect light, which can cause difficulties in data acquisition. In such cases, we use specialized techniques, such as a matting agent, which reduces reflections and improves measurement accuracy. An additional limitation is scanning very small elements with a complex structure, which may require microscopic precision and additional preparatory processing before digitization. Attention should also be paid to 3D scanning of holes, the depth of which can be scanned is closely related to their diameter.

Yes, we have mobile scanning devices that allow us to perform 3D scanning directly at the customer's premises or at any other designated location. Thanks to the use of portable laser scanners, we can perform precise measurements both in industrial conditions and in hard-to-reach locations. Field scanning is particularly useful for large-sized objects, industrial installations, monuments and elements that cannot be transported.

We use advanced additive technologies, including FDM (Fused Deposition Modeling) and SLS (Selective Laser Sintering). FDM technology enables fast and economical production of prototypes and elements with high mechanical resistance, which makes it an ideal solution for industrial and engineering applications. In turn, the SLS method allows printing of complex geometries without the need for support structures, while offering high strength and precision. By using both technologies, we can adjust the process parameters to the specific technical and functional requirements of a given project.

We offer 3D printing in a wide range of materials adapted to various industrial and engineering applications. In FDM technology, we use materials such as PLA, ABS, PETG, TPU (elastomers), as well as advanced composites, e.g. nylon PA6/PA12 reinforced with carbon fiber (15%) or glass fiber (15-30%), which allows to obtain elements with increased stiffness and mechanical resistance. In SLS technology, we use polyamide powders (PA12, PA11) and their reinforced versions, which allows to produce precise, strong and lightweight components without the need to use supports. In addition, depending on the project requirements, we can use specialist materials resistant to high temperature, chemicals or abrasion.

Yes, we offer a comprehensive 3D modeling service based on technical documentation. We use the technical drawings provided by the client in CAD formats (e.g. STEP) to create a digital model, which can then be optimized for 3D printing. In the absence of a 3D model, our engineers can perform the reverse engineering process, which consists of recreating the geometry of the object based on 3D scanning or technical documentation.

We have a wide range of 3D printers that allow for the production of both small, precise components and large-sized elements. Depending on the technology, the maximum dimensions of a single print are up to 380 x 420 x 460 mm for FDM technology and up to 165 x 165 x 300 mm for SLS. In the case of projects requiring larger sizes, we use the modular 3D printing method, which involves segmenting elements and then connecting them using dedicated assembly techniques, such as chemical bonding, screws or latches.

Yes, printed elements can be characterized by high mechanical, chemical and thermal resistance, depending on the technology and material used. Elements made of nylon offer excellent resistance to abrasion and chemicals, which makes them useful in industries such as automotive or machinery. Components printed in FDM technology, especially those made of ABS or fiber-reinforced nylon, can be used as replacements for elements produced using traditional methods, while offering lightness and strength.

Reverse engineering is an advanced process of reconstructing a digital three-dimensional model based on an existing physical object. This technique allows for precise geometry reproduction, structural analysis and design optimization of mechanical elements. It is used both to reproduce parts for which there is no technical documentation, and to improve existing designs to increase their efficiency, strength or ergonomics. Reverse engineering plays a key role in component modernization, replacement production and research and development processes.

Yes, we offer the possibility of editing and modifying existing CAD projects based on provided files or obtained data from 3D scanning. As part of this service, we can optimize the design, improve technical parameters, adapt the project to new operating conditions or implement material changes. Modifications can include both minor corrections and comprehensive redesign of the element in accordance with the customer's requirements. Each project is analyzed to ensure full compatibility with the production process and technological requirements.

In the process of reverse engineering and quality control we use advanced tools for processing 3D scanning data such as Geomagic Design X/Control X. For geometry analysis and modeling we use CAD software such as SolidWorks and Fusion 360.

Yes, we provide a complete prototyping process including 3D scanning, CAD modeling, 3D printing, and functional testing. Once we have a digital model, we can prepare a prototype made using various 3D printing technologies, such as FDM or SLS, depending on the material and mechanical requirements. Additionally, we offer fit analysis and component functionality assessment, which allows for verification of the design before implementation into series production.

Reverse engineering is used in a wide range of industries, including automotive, aviation, machinery, energy, and medicine. In the automotive sector, it is used to reproduce hard-to-find or discontinued spare parts. In aviation, it enables the modernization and certification of components in accordance with applicable standards. The machinery industry uses this technology to optimize the design and extend the life of devices. In medicine, reverse engineering is used for personalized implants and prostheses, individually adapted to the patient.

Yes, we offer a comprehensive service of creating CAD models based on 3D scanning. The models we create are fully editable and compatible with leading engineering programs such as SolidWorks, Autodesk Inventor or Siemens NX. This process includes geometry reconstruction, surface smoothing, point cloud conversion to parametric solids and model optimization for further use in production or engineering analysis. Our services enable fast and precise digitization of components for their further analysis, modification or implementation in production.

We offer advanced quality control methods that include dimensional inspection using modern 3D scanners from SCANTECH. We use precise measurement technologies that allow for the analysis of both linear dimensions and complex spatial geometries. Our methods include comparing scanned data with CAD models, generating deviation maps and detecting non-conformities with respect to required tolerance standards. We also use statistical data analysis methods, which allows for detailed monitoring of the repeatability and stability of production processes.

Yes, we provide comprehensive measurement reports that include detailed analyses of the dimensional compliance of scanned objects. The reports are generated based on comparisons of scanned models with CAD documentation and include, among others, deviation visualizations, tolerance charts and detailed measurement data. Depending on the customer's requirements, the reports can be adjusted to specific quality standards, ensuring full transparency and compliance with international quality control standards.

Yes, we offer the possibility of conducting quality inspections directly at the customer's premises. In the case of initial deviation analysis, we use mobile 3D scanners, which allow for a quick comparison of the provided CAD model with the scanned object and generation of a deviation color map. On the other hand, detailed measurement reports, requiring advanced analysis and more accurate data processing, are carried out at our company's headquarters.

Yes, we perform detailed analyses of dimensional deviations, which involve comparing the actual object with the reference CAD model. As part of the analysis, we assess the compliance of the shape and dimensions with specified tolerances, generate deviation maps and create cross-sectional graphs of geometric differences. Additionally, if a deeper analysis is necessary, we can perform a statistical assessment of deviations in order to identify production trends and potential sources of errors, which allows for the optimization of production processes and improvement of the quality of final products.

To contact our team, you can use several convenient communication channels:

E-mail – We respond to inquiries as quickly as possible, offering detailed information and technical advice.

Telephone – We are available during working hours, providing quick answers to questions and technical consultations.

Contact form on the website – You can send an inquiry directly through our website, which allows you to specify your needs and quickly obtain a tailored offer.

Online meetings – In the case of more complex issues, it is possible to arrange a video conference with our engineers and technical advisors.

Meetings at the office – We are open to meeting at our office to answer any questions and provide technical advice. We invite you to schedule a convenient time for you.

Our priority is fast and effective support, which is why we make every effort to ensure that the answers are comprehensive and tailored to the individual needs of our customers.

Yes, we provide professional technical advice on our services and technologies. Our specialists have extensive experience in reverse engineering, 3D printing and quality control, which allows us to support clients at every stage of project implementation.