Quality control in industry

In today's rapidly evolving industry, quality control plays an important role. It ensures that products meet the required standards and specifications. Traditional quality control methods, while effective, are often time-consuming and expensive. In response to these challenges, 3D scanning technology is gaining popularity as a tool for more effective and much more accurate quality control. 3D scanning not only speeds up inspection processes, but also provides more detailed data, which allows us to better understand the product and its possible defects.

3D scanning is a process of digitizing three-dimensional objects using special devices such as laser scanners, structural light scanners, or photogrammetry. These devices record data on the shape and surface of the object, creating its digital representation in the form of a point cloud. The point cloud is a collection of three-dimensional coordinates that can be processed into a 3D model. This model can then be analyzed, compared with the original CAD (Computer-Aided Design) project, and used for various purposes, such as quality control, reverse engineering, or additive manufacturing.

The Role and Tasks of 3D Scanning in Quality Control

1. Speed and Efficiency

One of the greatest advantages of 3D scanning in the context of quality control is its speed. Traditional inspection methods, such as manual measurements or using coordinate measuring machines (CMMs), can be time-consuming, especially for complex shapes. 3D scanners can scan an entire object in a matter of minutes, providing a complete set of data about its geometry. This not only speeds up the inspection process but also allows for examining more samples in a shorter time.

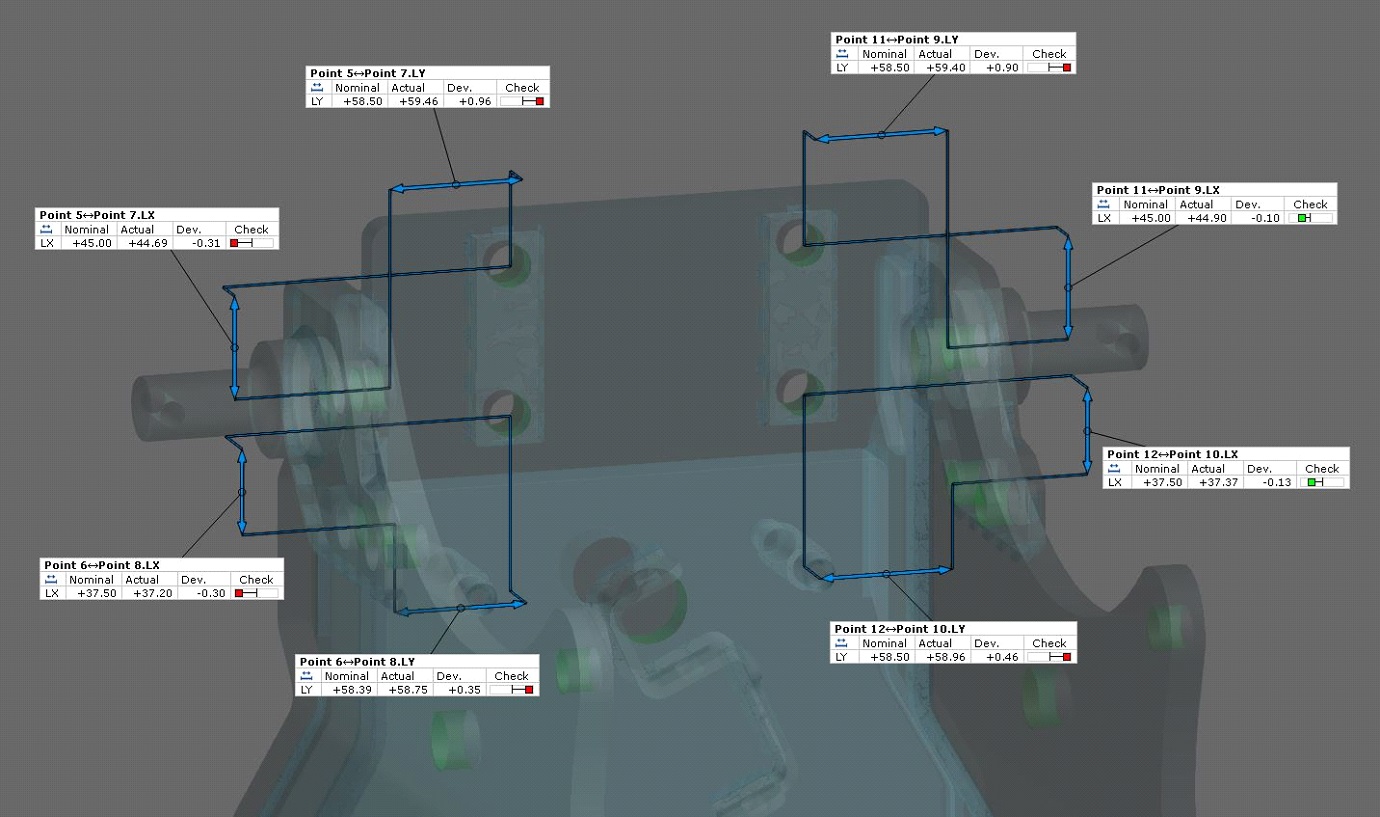

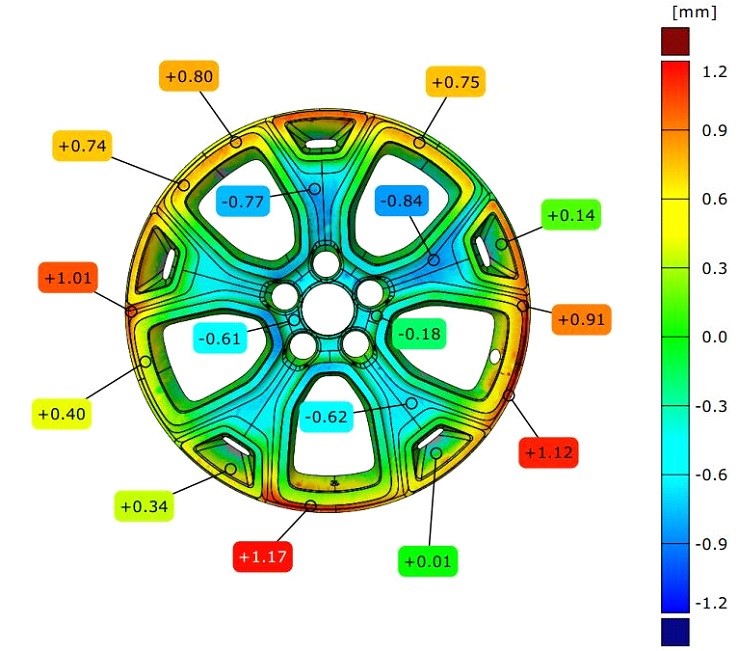

2. Accuracy and Precision

3D scanning offers extremely high measurement accuracy, often in the micrometer range. This allows the identification of even the smallest deviations from the norm that might be missed using traditional methods. Precise data can be crucial in industries that require the highest quality standards, such as aerospace, automotive, and medical sectors.

3. Complex Geometries

Today's products often feature complex shapes and structures that are difficult to measure using traditional methods. 3D scanning allows for easily capturing complex geometries, including surfaces, curves, and internal features that would be difficult or impossible to inspect otherwise.

4. Automation and Repeatability

3D scanning processes can be automated, which eliminates human errors and ensures repeatable measurements. Automation is especially important in mass production, where consistency and quality must be maintained at every stage. 3D scanners can be integrated into production lines, enabling continuous quality control without production interruptions.

Examples of 3D Scanning Applications in Quality Control

⦁ Automotive Industry

In the automotive industry, where precision and quality are key, 3D scanning is widely used to inspect car parts such as engines, transmissions, or bodies. With 3D scanning, manufacturers can quickly and accurately compare finished products to CAD models, identifying any deviations and defects. An example is the analysis of complex engine castings, where even the smallest imperfections can affect engine performance and durability.

⦁ Aerospace

The aerospace industry places extremely high demands on quality control due to safety and reliability. 3D scanning is used to inspect components such as turbines, wings, and fuselages. The ability to accurately measure and analyze complex geometries is invaluable, especially for composite materials and advanced metal alloys.

⦁ Medical Industry

In medicine, where precision is key, 3D scanning is used for producing implants, prostheses, and surgical instruments. 3D scanning enables the creation of precise anatomical models of patients, allowing for personalization and optimization of implants and better planning of surgical procedures.

Despite these challenges, the future of 3D scanning in quality control looks promising. Advances in technology and decreasing equipment costs make 3D scanning increasingly accessible. Integrating 3D scanning with other technologies such as artificial intelligence and big data analysis opens up new possibilities for automating and optimizing quality control processes. In the future, we can expect even greater precision, speed, and versatility of 3D scanning, which will revolutionize the industry and set new standards in quality control.

3D scanning does not operate in isolation but is often an integral part of larger production management systems such as PLM (Product Lifecycle Management) and MES (Manufacturing Execution Systems). Integrating 3D scanning data with these systems enables tracking and documenting quality at every stage of the product lifecycle. This allows better data management, trend identification, and quick responses to potential quality issues. Combined with data analysis, manufacturers can gain insight into production processes, leading to continuous improvement and optimization.

3D scanning technology is also used in maintenance and repair, especially in sectors such as energy, oil, and heavy industry. 3D scanning allows for precise analysis of the technical condition of equipment and infrastructure, identifying wear, cracks, and other defects. Based on scan data, repairs and replacements can be precisely planned, increasing the efficiency of maintenance activities and minimizing the risk of failures. In the energy sector, where reliability and safety are priorities, 3D scanning is indispensable for ensuring continuity of work and optimal resource management.